Hematite and Itabirite

World-class iron ore resource

What is hematite?

Hematite is a black, grey or reddish-coloured mineral which is mined as the main source of iron.

Hematite has traditionally formed the bulk of global iron ore production, and high-grade hematite is often referred to as “Direct Shipping Ore” or “DSO” because it is mined and beneficiated using a relatively simple crushing and screening process before being exported for use in steel mills.

Hematite is often cheaper to process than other forms of iron ore as it generally does not require beneficiation due to its higher iron content. However, hematite ores may contain higher concentrations of contaminant elements (such as phosphorus, alumina and silica) and may therefore need to be blended prior to smelting. Export grade hematite ores generally grade above 60% iron content.

What is itabirite?

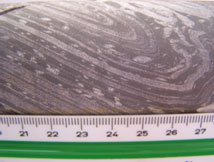

The term itabirite was first coined in Brazil to describe a number of major hematite orebodies in Brazil’s southern system. Itabirite mineralisation is a metamorphosed iron formation composed of iron oxides (hematite, magnetite, martite), abundant quartz, very rarely mica and other accessory minerals.

Brazil’s itabirite deposits range in scale from 1 to 4 billion tonnes, with average grades of between 37% Fe and 52% Fe. The mineralisation is beneficiated to produce high-grade concentrate or pellets, which is then sold to steel mills.

The key commercial benefit of concentrate produced from itabirite ore is its quality. The concentrate is high grade with very low phosphorous, alumina and silica content. It is keenly sought by mills seeking Direct Reduction (“DR”) grade feed or pellets, and by mills seeking high-grade product that they can blend with lower grade ore, particularly DSO ores which are showing increasing levels of alumina and phosphorous contamination.

Beneficiation of the itabirite resource at Mbarga will utilise conventional grinding and reverse flotation to produce a combination of Direct Reduction (DR) grade concentrate grading 68% Fe and Blast Furnace (BF) grade concentrate grading 65% Fe depending on target grind size. This beneficiation process is technically straightforward, uses no new technology, and has been technically proven at numerous iron ore projects around the world.